Tapping into the Potential of Cognitive Factories

In the quest for operational excellence, businesses are continually exploring innovative strategies to enhance productivity and drive growth. One such strategy that is quickly gaining traction in the industrial sector is the concept of cognitive factories. This article delves into the rise of cognitive factories, their impact on productivity, and the challenges they present.

Background: The Emergence of Cognitive Factories

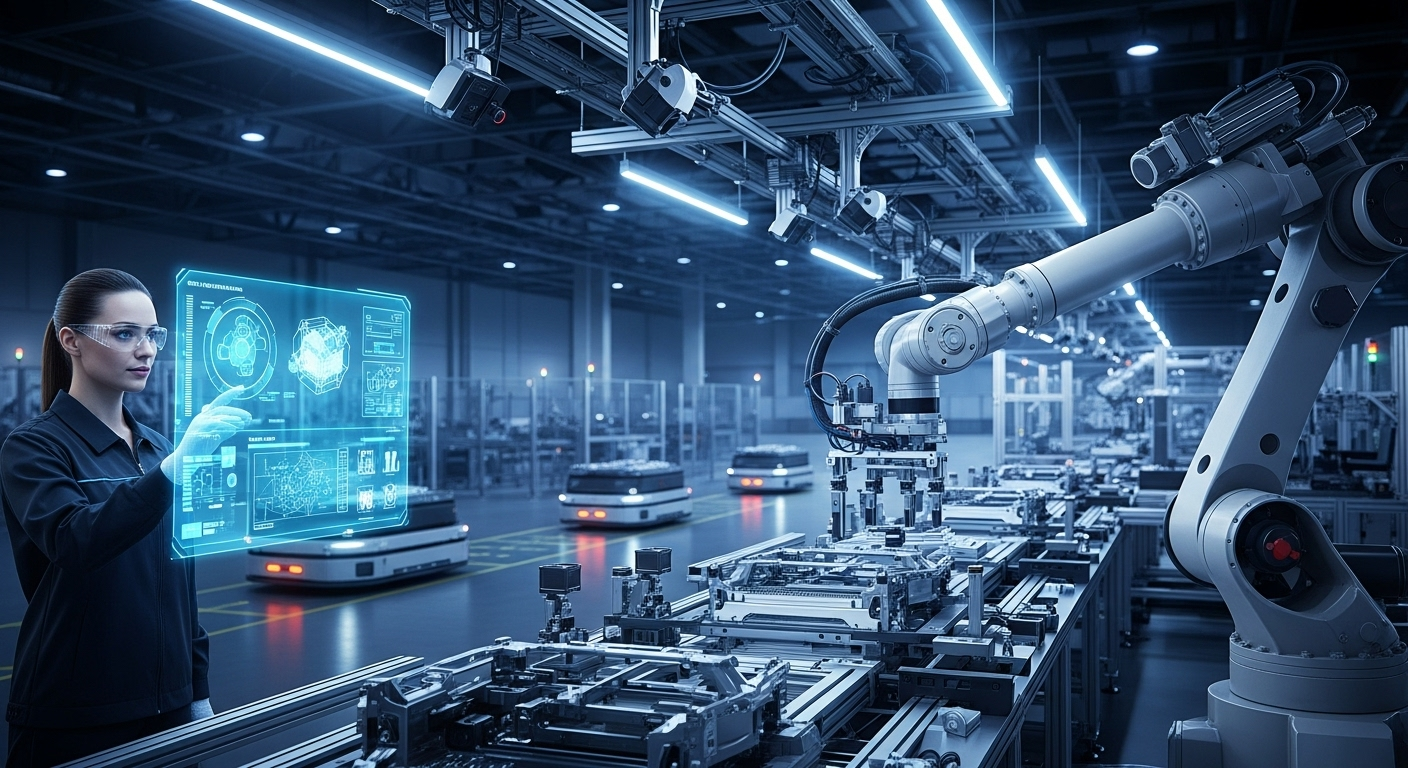

Cognitive factories are essentially smart factories that leverage advanced technologies like machine learning, artificial intelligence, and big data analytics to optimize operations and increase efficiency. This concept emerged from the need to manage the increasing complexity of industrial processes and the desire to leverage the vast amounts of data being generated in factories. Cognitive factories represent the convergence of the physical and digital worlds, where machines and systems can analyze data, learn from it, and make decisions or predictions based on it.

Current Trends and Expert Insights

The rise of cognitive factories is being fueled by several key trends. First, there’s the increasing adoption of Industry 4.0 technologies, which are enabling factories to become smarter and more connected. Second, businesses are recognizing the value of data and analytics in driving decision-making and operational efficiency. According to a report by Deloitte, cognitive factories can boost productivity by up to 20% and reduce downtime by up to 50%.

Impact, Benefits, and Challenges of Cognitive Factories

Cognitive factories offer multiple benefits. They can significantly enhance operational efficiency by automating complex processes, improving decision-making, and reducing errors. They can also enhance flexibility and adaptability, enabling factories to better respond to changes in demand or disruptions in the supply chain.

However, implementing a cognitive factory is not without its challenges. It requires significant investment in technology and infrastructure, as well as a skilled workforce capable of managing and analyzing the data. There’s also the challenge of integrating various systems and technologies, and ensuring data security and privacy.

Decoding Practical Applications: Industrial Insights

-

Cognitive factories can leverage predictive maintenance, using machine learning algorithms to predict equipment failures and schedule maintenance, thereby reducing downtime and improving efficiency.

-

They can also use artificial intelligence to optimize production planning and scheduling, taking into account factors like demand forecasting, resource availability, and production constraints.

-

Cognitive factories can use data analytics to improve quality control, identifying patterns and trends that could indicate potential quality issues.

While cognitive factories represent a significant leap forward in industrial operations, businesses must carefully consider the challenges and requirements before embarking on this journey. Nevertheless, those that successfully navigate this transition stand to reap substantial benefits in the form of increased productivity, efficiency, and competitiveness.

As we move towards the future, cognitive factories will undoubtedly play a pivotal role in shaping the industrial landscape. It is a testament to the power of data and technology in driving industrial progress and a sign of the exciting possibilities that lie ahead in the realm of smart manufacturing.